Excellence in aerospace manufacturing

Redefining aerospace standards through precision and innovation

Our range of aerospace services

High-performance materials

High-performance materials

Machining of aerospace-grade materials like titanium and aluminum alloys for optimal strength and durability.

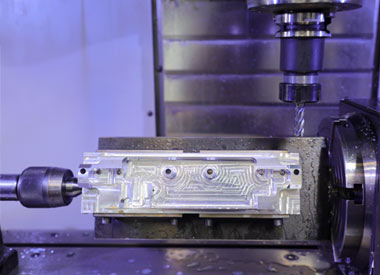

Precision CNC machining

Precision CNC machining

Expert CNC machining for aerospace components with tight tolerances and superior surface finishes.

Complex geometry machining

Complex geometry machining

Specialized in machining intricate features crucial for aerodynamic and structural performance.

Multi-axis machining

Multi-axis machining

Utilizing advanced multi-axis CNC machines for precision and efficiency.

Quality assurance

Quality assurance

Stringent quality control processes ensure components meet or exceed industry standards.

Why choose us for aerospace parts manufacturing?

Extensive experience

Years of experience in aerospace machining, serving industry leaders with precision-engineered components.

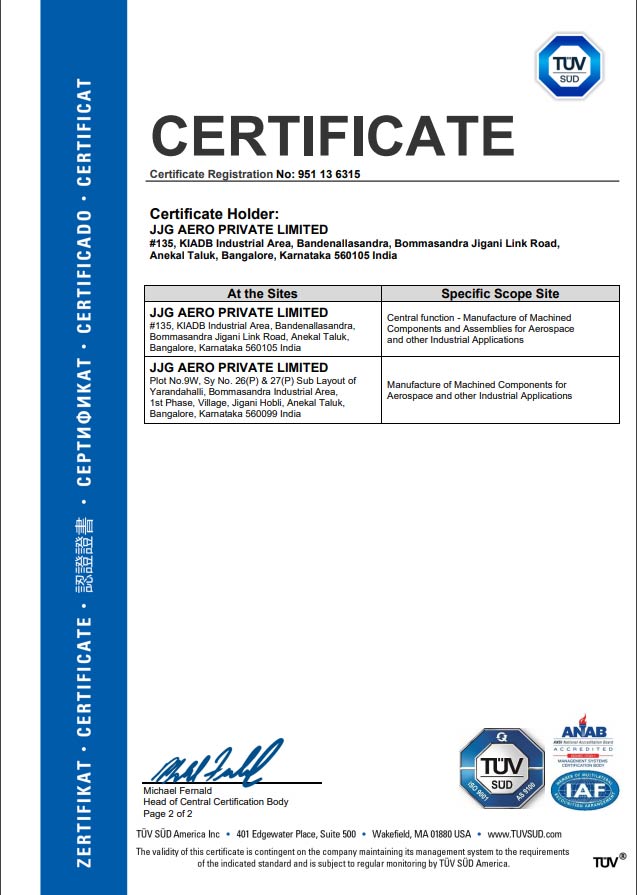

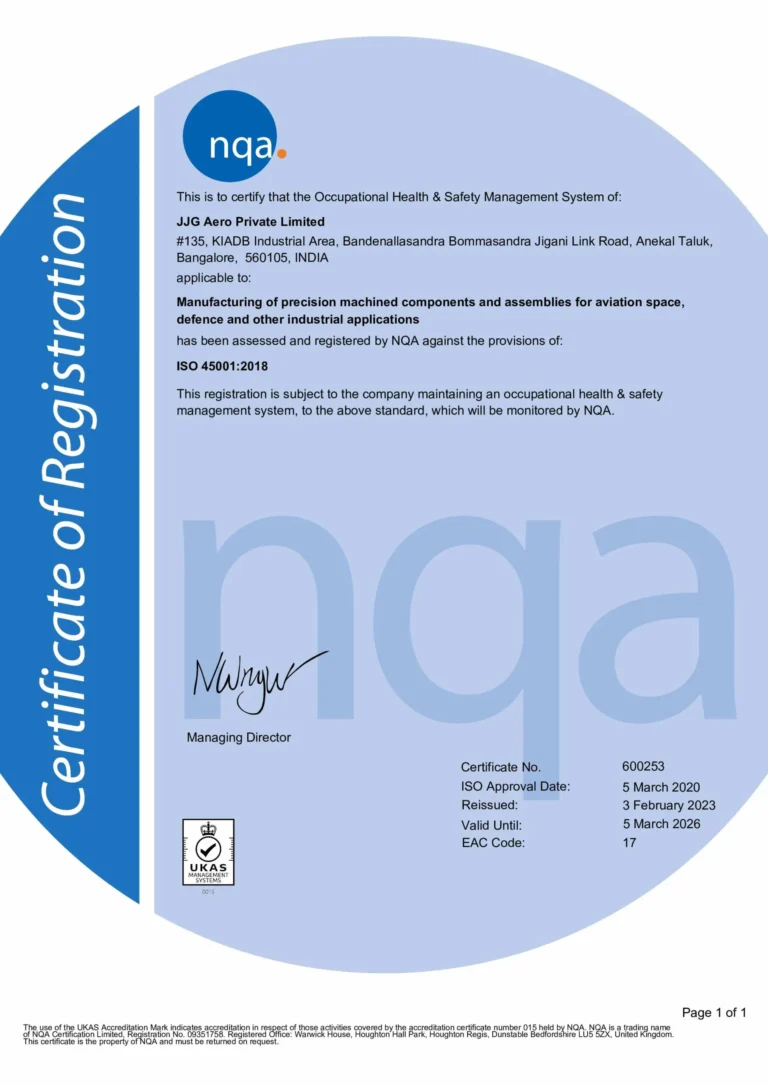

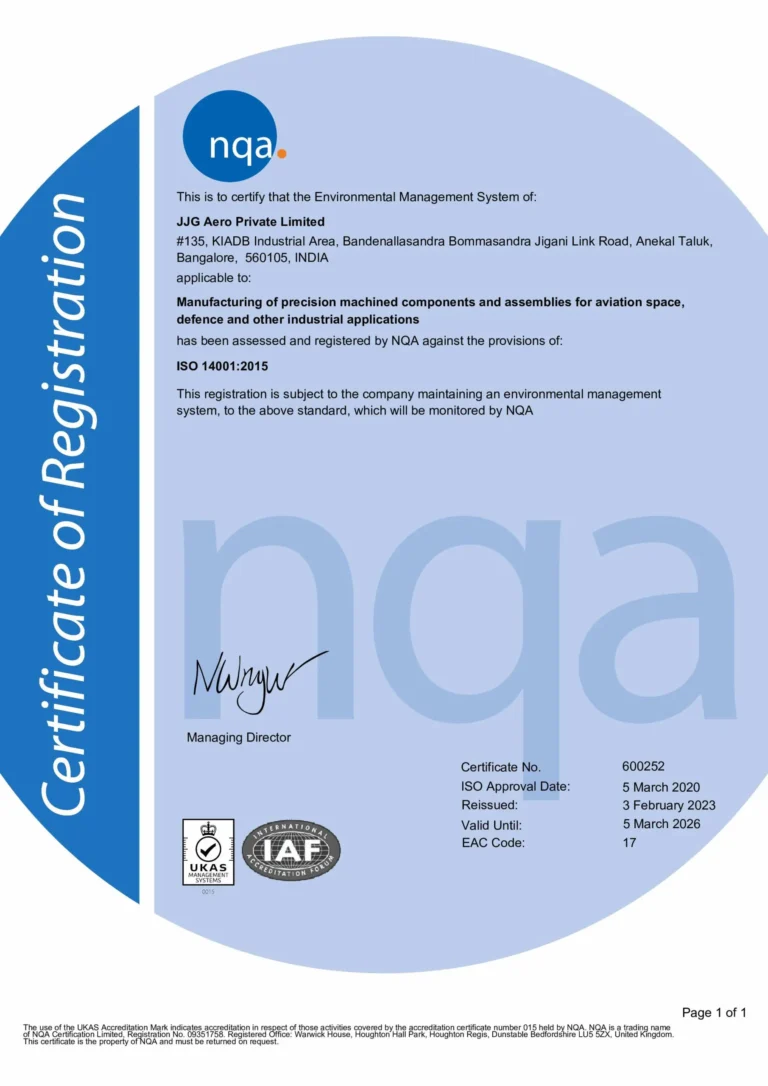

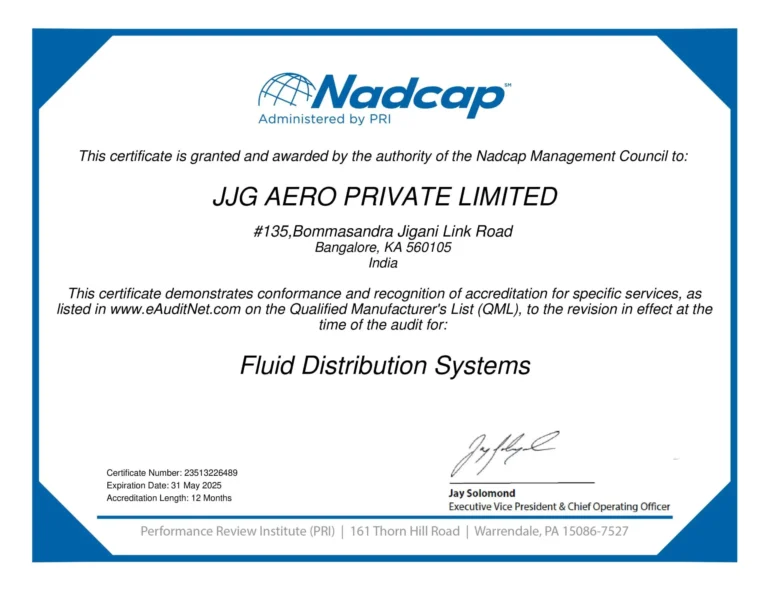

Industry compliance

Adherence to stringent aerospace industry standards and certifications, ensuring regulatory compliance and quality assurance.

Customized solutions

Tailored machining solutions to meet the unique requirements of aerospace applications, from design to production.

Advanced technology

State-of-the-art CNC machines and cutting-edge technology for efficient and high-quality aerospace part manufacturing.

Dedicated team

Skilled engineers and technicians committed to delivering excellence in every aspect of aerospace part production.

Reliable partnerships

Trusted by leading aerospace OEMs for our reliability, responsiveness, and commitment to delivering on time, every time.

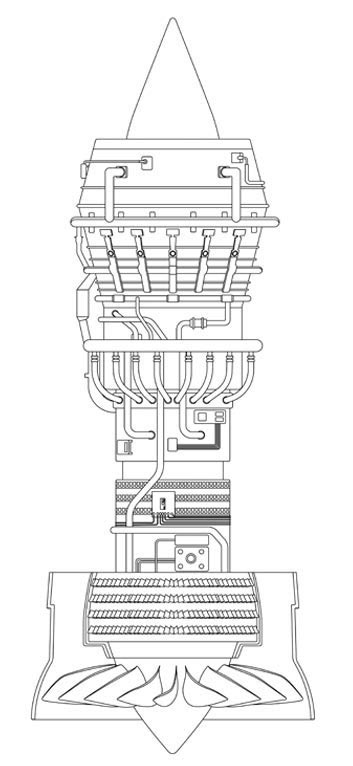

Applications in aerospace machining

Seating & Cargo System

Precision-machined components ensure safety and comfort in aerospace seating and cargo systems.

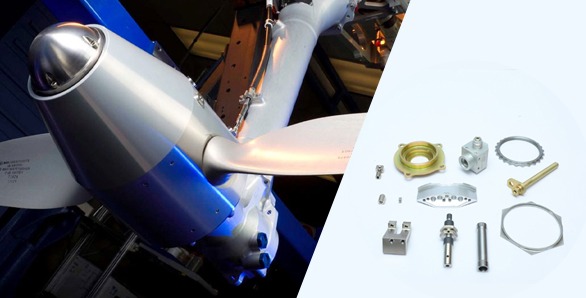

Landing Systems

Critical parts manufactured to exact specifications for reliable and safe aircraft landing systems.

Electric System

High-quality components supporting the efficient operation of aerospace electrical systems.

Air Management Systems

Precision-engineered parts for maintaining optimal air quality and pressure in aircraft cabins.

Fluid System

Precision machining for components integral to the smooth operation of fluid systems in aircraft.

Actuation

Expertly machined components crucial for the precise control and movement of aerospace actuators.

Aerospace machining solutions

-

Turning

-

Turnmill

-

Milling

-

Centerless Grinding

-

Surface Grinding

-

Cylindrical Grinding

-

Deep Hole Drilling

Turning

Turning

Turning

Precision turning capabilities for components up to 60 kg in weight and diameters ranging from 2 to 250 mm.

Turnmill

Turnmill

Turnmill

Versatile 5-axis machining for complex parts, including small-diameter components with lengths under 250 mm.

Milling

Milling

Milling

High-speed milling with torque capabilities of 175 Nm and a bed size of 1027x540x540 mm for efficient production of aerospace components.

Centerless Grinding

Centerless Grinding

Centerless Grinding

Precision grinding method for achieving tight tolerances and smooth finishes on cylindrical components.

Surface Grinding

Surface Grinding

Surface Grinding

Surface finishing process for achieving flat and smooth surfaces on aerospace components.

Cylindrical Grinding

Cylindrical Grinding

Cylindrical Grinding

Precision grinding technique for producing cylindrical shapes with high accuracy and surface quality.

Deep Hole Drilling

Deep Hole Drilling

Deep Hole Drilling

Specialized drilling process for creating deep holes in aerospace components with precision and efficiency.

Our quality assurance

Dimensional inspection

Precision verification of critical dimensions using advanced metrology tools for aerospace component conformity.

Non-destructive testing (NDT)

Detection of surface and subsurface defects through non-invasive methods, ensuring component integrity without compromise.

Process control and monitoring

Continuous monitoring and control of manufacturing processes to maintain consistent quality and adherence to specifications.

Certifications and compliance

Achievement of AS9100, NADCAP, and customer-specific certifications, demonstrating a commitment to aerospace quality requirements.

Continuous improvement initiatives

Implementation of continuous improvement methodologies to drive efficiency, quality enhancement, and innovation in aerospace machining processes.